HVAC (Heating, Ventilation, & Air Conditioning) validation continues to be a source of anxiety for many manufacturers of pharmaceutical & biologic products. HVAC validation is likely to be successful when good strategy and planning are involved in the process. QTS guides you in the right direction.

HVAC and Clean Room Validation

There are many factors to consider in HVAC validation and it is best to take on a realistic approach based on good science, business and compliance sense. We are familiar with HVAC validation requirements and industry standard validation practices for your product forms, what documented evidence is needed for your HVAC Systems (e.g. drawings, specifications, balancing reports), and we know if your control systems are strong enough to be validated.

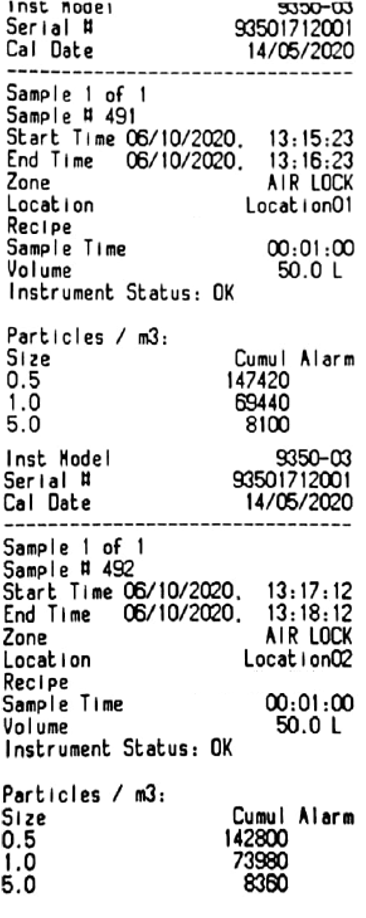

particle counter

Photometer

Particle Counter

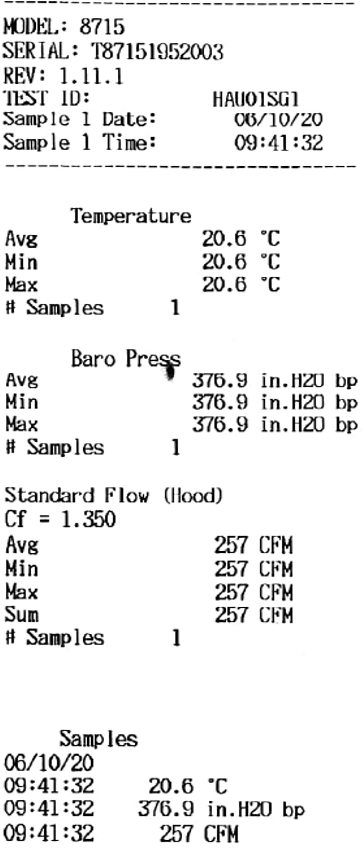

Air Capture Hood

Anemometer

We then develop a general strategy consisting of the following factors:

Ø Classification of HVAC systems as GMP or non GMP systems.

Ø Determination of what documentation you have and what

documentation you need to create before validation begins.

Ø Development of targets for differential pressure, room air

changes, temperature and humidity.

Ø Concentration of validation efforts on the areas where there

is a direct product impact.

Ø Validation of Building monitoring system that are connected

to HVAC systems.

CLEAN ROOM VALIDATION

ISOLATOR VALIDATION

Ø Filter Integrity Leak Test (using PAO).

Ø Recovery period study.

Ø Calculation of air changes / hour in room.

Ø Filter face air velocity measurement.

Ø Air velocity / CFM measurement in Duct.

Ø Air flow visualization test.

Ø Air borne particulate matter monitoring.

Ø Room temperature / RH monitoring.

Ø Air velocity / CFM measurement across Relief/Bleed air filter.

Ø Air velocity / CFM measurement across fresh air filter.

Ø Noise level.

Ø Particle count test.

Ø Light intensity.

Ø Recovery time determination.

Ø Air Flow velocity.

Ø Smoke Pattern.

Ø Gauntlet breach air velocity Filter Leak.

Thermal Print of Air Velocity Measurement Test

Air Velocity Measurement test is done using

TSI make Air Capture Hood & for equipment’s Matrix / Hot Wire Anemometer is used.<br/>

Ø Calculation of air changes / hour in room.

Ø Filter face air velocity measurement.

Ø Air velocity / CFM measurement in Duct

Ø Air velocity / CFM measurement across Relief/Bleed air filter.

Ø Air velocity / CFM measurement across fresh air filter